We manufacture healthy, high-performing thermal insulation made of hemp, creating energy-efficient homes while also giving back to the environment by sequestering Carbon Dioxide.

Why we do, what we do.

Since 2013, we’ve manufactured the most sustainable building materials on the planet. Our plant-based insulation benefits both people and the planet because they are derived from carbon-capturing, agricultural industrial hemp, a non-toxic renewable feedstock.

Hempitecture imagines a tangible future where natural, non-toxic building materials like HempWool become the industry standard. We believe by producing natural building materials, we can significantly decarbonize built environments. In doing so we help create healthier buildings, happier people, and a healthier planet.

It starts with a seed.

Fiber Hemp genetics are planted in the earth, marking the beginning of our product lifecycle.

Seeds grow into hearty, robust stalks.

The stalks mature from seed in just 4 months time, growing into a fiber rich, dense stand.

The field is cut.

When ready, the Fiber Hemp stalks are cut and left in the field to ret.

Processing into fiber.

The retted stalks are baled, transported to the processing facility, and turned into refined fiber.

Fiber bales.

Refined fiber is baled, and ready for processing by Hempitecture.

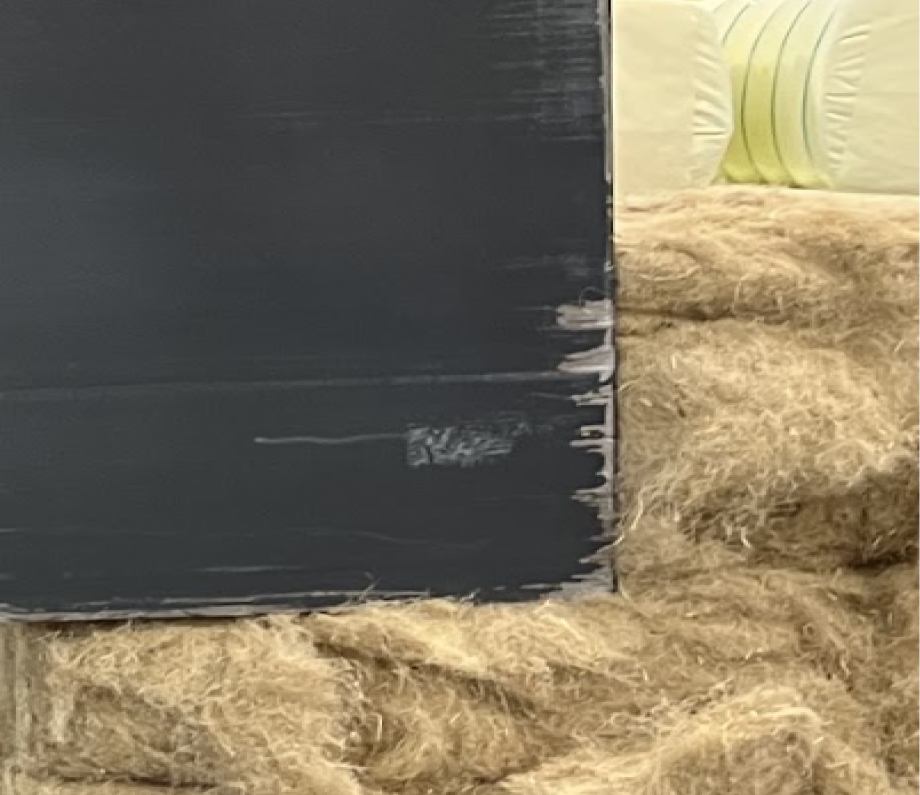

From fiber to product.

The fiber is converted into a range of building materials in our state of the art manufacturing facility. From Field to Form, the product is now ready for your home.

of all greenhouse gas emissions are generated by built environments. This is a larger footprint than any other sector.

We need to rethink building materials and break the current modalities in manufacturing.

Embodied Carbon is the sum of all greenhouse gas emissions to produce materials for a building.

Operational Carbon is the amount of carbon emitted during the in-use phase of a building.

To truly make a global impact, first we must lower embodied carbon in building materials.

Secondly, the low-carbon materials we use, must contribute to energy- efficient built environments.

Biobased materials.

The majority of a building’s total embodied carbon is released at the beginning of a building’s life.

Unlike operational carbon, there is no chance to decrease embodied carbon after the building is constructed.

Hempitecture’s products solve for both embodied and operational carbon emissions

Greening construction with our biobased insulation, cutting embodied carbon impact sustainably.

02

06