We can supply you the materials to create healthy, high-performing thermal insulation made from hemp, creating energy-efficient homes while also giving back to the environment by sequestering Carbon Dioxide.

The sustainable alternative

The sustainable alternative

Hempitecture, a forefront figure in US hemp construction, collaborates with architects, builders, engineers, and developers. Together, we create energy-efficient, non-toxic, and carbon-absorbing environments. Looking to incorporate hemp-based insulation in your next project? We’re here to assist.

Schedule a call with a Hempitecture Technician today and let’s get started!

Materiales matter

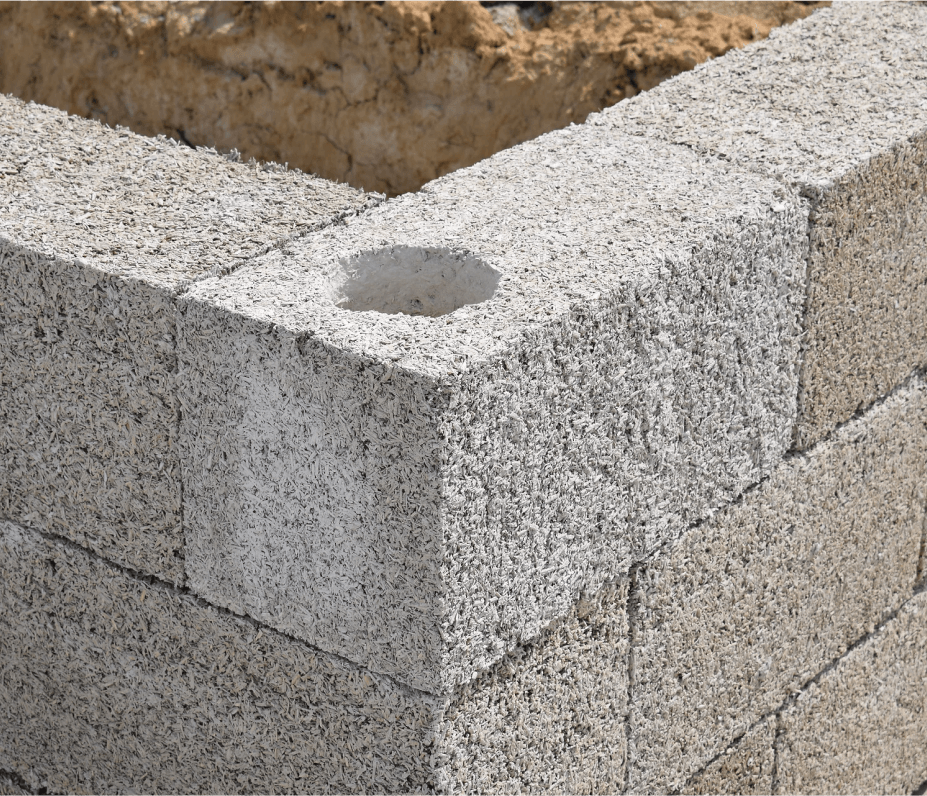

Hempcrete, or Hemp + Lime, is an eco-friendly building material. It blends the inner core of industrial hemp with a lime-based binder, creating a bio-composite. Although not a structural element, Hempcrete serves as insulation between frame members, reducing racking while internal framing supports structural loads.

Formulated by renowned lime experts

Hempitecture is excited to share our latest product, HempBinder.

Specially formulated for hempcrete building projects, this lime binder is manufactured and assembled in the US.

Optionality in Hempcrete

There are 2 primary ways of building with Hemp Lime composites. Learn which one is right for you below.

Regionalized supply chain

We work with fair & sustainably practicing farmers and processors in the United States and Canada to provide hemp core to building grade specification.

From the earth and into your home.

Acoustic insulation

The importance of hempcrete binder can never be underestimated and our products were carefully selected and tested to create long lasting biocomposites that are resilient, healthy, and high performing.

Hempitecture uses a specifically formulated mineral based binder that is ideal for bonding hemp core both in spray applied and cast in place methods.

We believe your walls should not just keep you comfortable, they should help clean the environment.

The materials used to create hempcrete biocomposites absorb CO2 during the curing process. Additionally, CO2 is absorbed and offset during the life cycle of the industrial hemp plant. Few decisions in your construction program can take as much carbon out of the atmosphere as deciding to build with hempcrete.

High thermal absorption capacity.

ASTM E84 certified.

100% natural biobased materials. No VOCs and contain no red-listed ingredients.

Preserves efficiency by eliminating all thermal bridging in the envelope.

Code Compliant

Hempitecture is the first company in the US to have its hemp lime formulation tested to the rigors of ASTM E84. This fire resistance test proved conclusively that our material is fireproof.

In fact, on a scale of 0-450, with 450 being extremely flammable, our samples scored 0 for flame spread and smoke developed. To learn more, view the report.

We’re here to guide you

Book a consulting call with Hempitecture

Consult with a Hempitecture Technician

30-35 min

Cast in place is an installation technique that involves using form boards and packing the hempcrete in between form boards to create walls. This is the most artisanal approach to hempcrete, however it can be labor intensive.

Hempcrete blocks offer a pre-cured insulation solution for sustainable building projects. There are a variety of block types to meet your needs. Hempitecture is a distributor of IsoHemp products. Contact Hempitecture for this special order product.