As the architectural world eyes sustainable and high-performance building solutions, specifying carbon-negative materials in a project is more crucial than ever. The challenge for architects has long been balancing aesthetics, performance, sustainability, and cost-effectiveness. Fortunately, with Hempitecture’s carbon-negative building materials, architects can seamlessly replace conventional, often toxic, insulation and finish materials without compromising quality or ease of use.

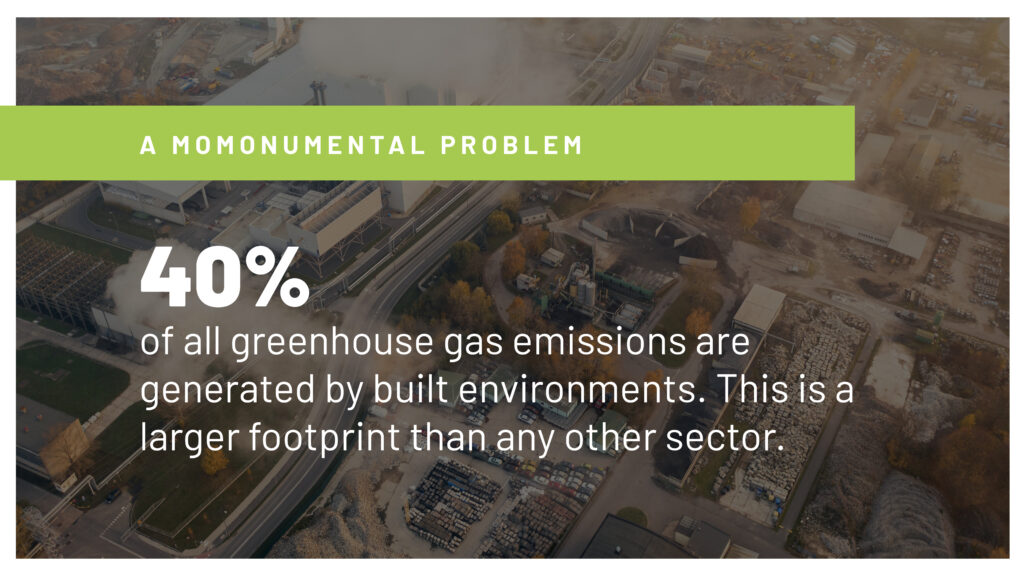

The Need for Sustainable Building Materials

The built environment is responsible for nearly 40% of global carbon emissions, with a significant portion stemming from embodied carbon in construction materials. Traditional insulation products, such as fiberglass and spray foam, rely on petrochemicals, which release harmful volatile organic compounds (VOCs) and contribute to greenhouse gas emissions. With increasing regulatory pressure and industry-wide commitments to reducing carbon footprints, architects are actively seeking materials that contribute to sustainability goals without requiring a radical shift in building techniques.

Hempitecture’s suite of materials offers a 1:1 replacement for conventional insulation while delivering unparalleled benefits, including improved indoor air quality, moisture management, and long-term energy efficiency. By specifying these products, architects can immediately impact a project’s sustainability metrics while ensuring occupants benefit from healthier, high-performance spaces.

Hempitecture’s Carbon-Negative Materials: A Direct Replacement for Toxic Alternatives

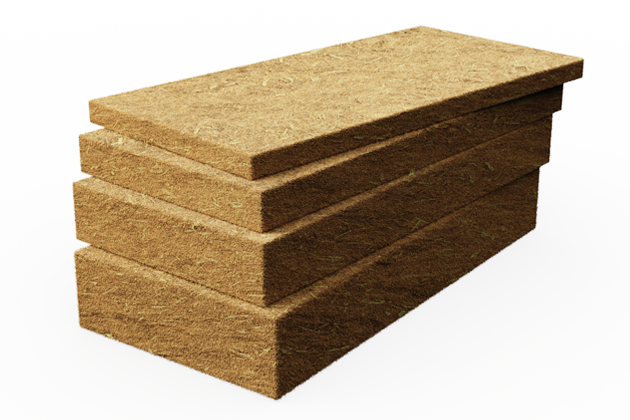

HempWool®: The Sustainable Insulation Alternative

HempWool® is a high-performance, bio-based insulation that serves as a direct replacement for fiberglass and mineral wool insulations.. Unlike these traditional materials, which contain synthetic binders and abrasive fibers, HempWool® is composed of 92% natural hemp fiber, a rapidly renewable resource that actively sequesters carbon throughout its growth cycle.

Key Benefits for Architects:

- 1:1 Installation: Can be friction-fit between studs and rafters, just like conventional batt insulation (which is why installers prefer it).

- Healthier Indoor Air Quality: Free from VOCs, formaldehyde, and toxic off-gassing (a direct benefit to homeowners).

- Superior Moisture Regulation: Naturally hygroscopic and vapor permeable, preventing mold and mildew growth.

- Thermal Performance: Comparable R-values to mineral wool and fiberglass, providing excellent thermal resistance.

- Acoustic Performance: Superior sound attenuation, improving indoor comfort in both residential and commercial applications.

FiberPad: A Natural, Carpet Underlayment

Unlike carpet padding made from petroleum-based urethane, synthetic latex or questionable post consumer content, FiberPad is made from an engineered blend of decorticated hemp and functional fibers.

Key Benefits for Architects:

- Acoustic Performance: An acoustical absorption layer that mitigates impact sound transmission in floor systems.

- Rebound: Engineered to withstand impact, contributing to a long lasting plush feel for carpet.

- Safety: Tested to industry flooring standards for flammability, including the Pill Test by Commercial Testing Services and is in accordance with international building code Standard A.

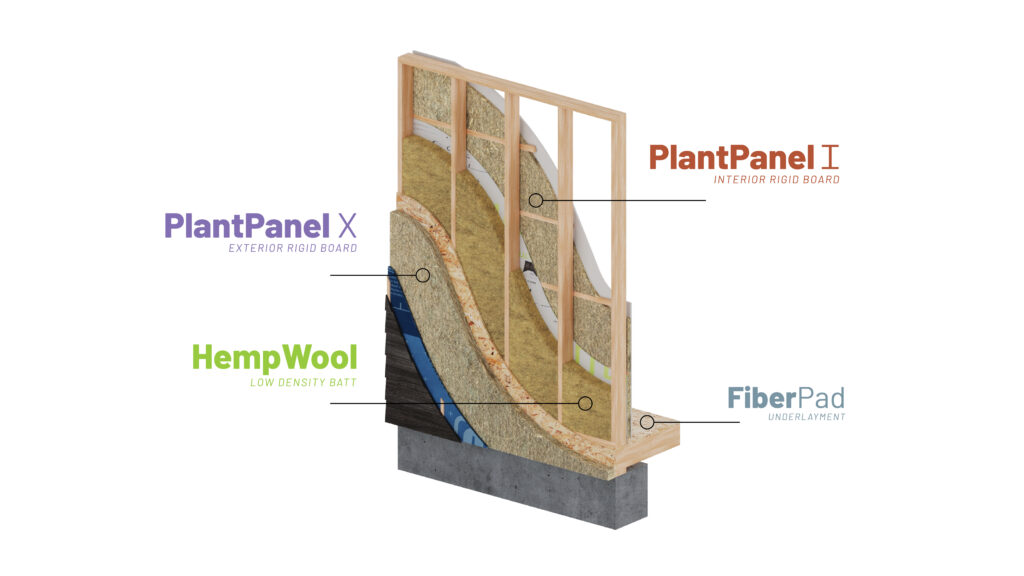

PlantPanel: Exterior/Interior Continuous Rigid Board

PlantPanel is used in split-insulation wall and roof assemblies with either a rain screen cladding or roofing material. With 100% biobased and recycled content, PlantPanel is a sustainable, low carbon continuous insulation solution that’s easy to install and safe to handle.

Key Benefits for Architects:

- Thermal Performance: At R3.25 / in, PlantPanel eliminates thermal bridging.

- Phase Shift: High Phase Shift Resistance means your house won’t overheat in summer and resists the coldest winter temperatures.

- Moisture Regulation: A rating of 27 Perms, meaning it remains vapor open and ideal for drying, which maintains performance.

- Acoustic Performance: Isolates 99% of sound from 1000 Hz to 1500 Hz in sound tube absorption testing.

Hempcrete: A Game-Changer for Thermal Mass and Breathability

Hempcrete is a bio-based building material composed of hemp hurd (the inner wooden core), lime binder, and water. It provides exceptional thermal mass, durability, and breathability, making it an ideal choice for exterior wall systems.

Key Benefits for Architects:

- Carbon-Negative: Stores more carbon than it emits over its lifecycle.

- Thermal Regulation: Creates a self-regulating indoor climate, reducing HVAC loads.

- Fire-Resistant: Non-combustible, making it a safer alternative to synthetic insulation.

- Durability: Resistant to pests, mold, and moisture-related degradation.

- Versatility: Suitable for new builds and retrofits, including residential, commercial, and institutional projects.

Architects Specifying carbon-negative materials & Meeting Sustainability Goals

Reducing Embodied Carbon

With increased emphasis on carbon accounting in the design and construction industry, specifying carbon-negative materials is a direct path to lowering a project’s embodied carbon. Every pound of hemp fiber used in Hempitecture’s products sequesters carbon from the atmosphere, significantly offsetting emissions associated with conventional materials. Third party validated LCA available!

Meeting LEED, WELL, and Passive House Standards

Hempitecture’s products align with leading green building certifications, including:

- LEED (Leadership in Energy and Environmental Design): Contributing points in categories like Materials & Resources, Indoor Environmental Quality, and Energy & Atmosphere.

- WELL Building Standard: Supporting occupant health through improved air quality and thermal comfort.

- Passive House Certification: Enhancing insulation performance and reducing heating and cooling demand.

Enhancing Biophilic Design and Occupant Well-Being

Biophilic design is gaining traction in modern architecture as a strategy to connect occupants with natural materials that improve well-being. Hemp-based materials not only align with this philosophy but also enhance indoor air quality, regulate humidity, and contribute to a more comfortable living environment.

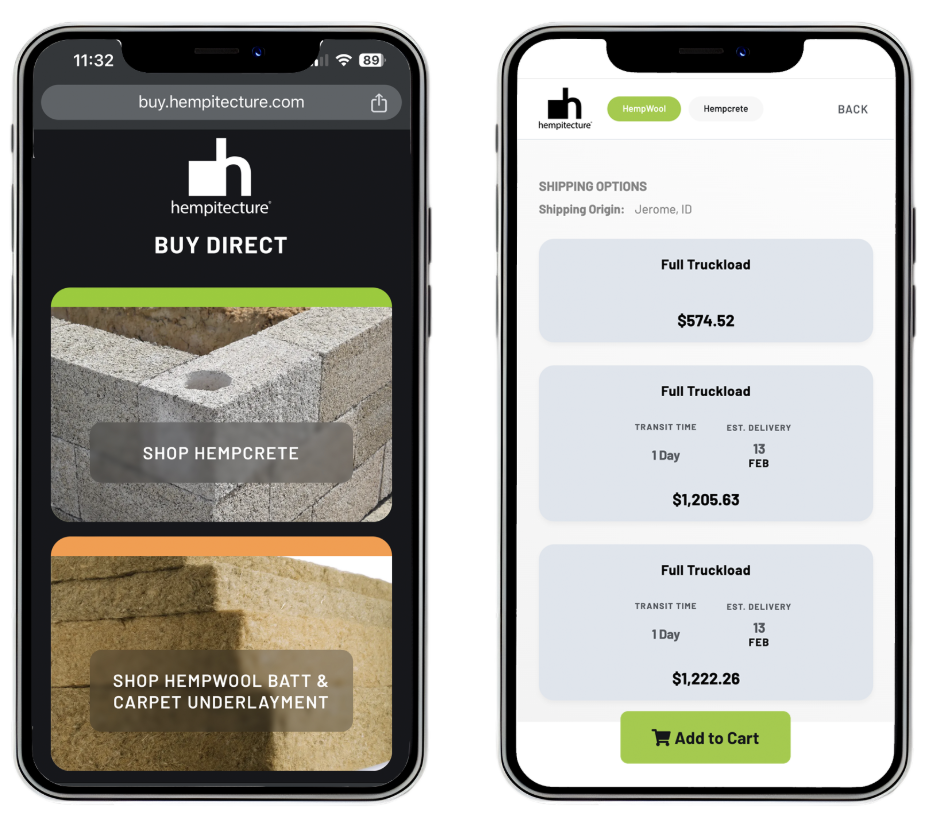

Simplifying the Specification Process

One of the most significant barriers to adopting new materials is the concern over integration with One of the most significant barriers to adopting new materials is the concern over integration with existing construction methods. Hempitecture has made it easy for architects to specify its products by providing:

Easy Quoting: Specifiers and contractors can easily quote and purchase, helping manage project budgets

Comprehensive Data Sheets: Covering thermal performance, acoustic benefits, and ASTM ratings.

Detailed Installation Guides: Ensuring smooth integration into standard construction workflows.

Leading the Future of Sustainable Architecture

Specifying carbon-negative materials isn’t just a step toward sustainability—it’s a leap forward in revolutionizing the built environment. By replacing conventional, abrasive, and petroleum-based insulations with natural, high-performance hemp-based solutions, architects can design buildings that are healthier, more resilient, and in harmony with the planet.

As regulations tighten and clients demand greener buildings, architects have an opportunity to lead the charge in reducing carbon footprints while enhancing the overall performance and livability of their projects. With Hempitecture’s easy-to-specify materials, the transition to sustainable architecture has never been more accessible.Are you ready to incorporate carbon-negative materials into your next project? Contact Hempitecture today for samples, technical support, get a quote, and guidance on specifying our revolutionary building solutions.