As Hempitecture grapples with the complex challenges of climate change and resource depletion, the necessity for businesses, especially in the built environment sector, to adopt a sustainability action plan is more urgent than ever. Our Sustainability Action Plan is not just a statement of intent; it’s a commitment to reducing our carbon footprint, championing conscious consumerism, and leading by example in conservation and sustainable commerce. To that end, in September 2018 Hempitecture incorporated as a first-ever Public Benefit Company to bring biobased insulation to the United States.

Understanding the significance of achieving net zero is at the heart of our plan. Net zero refers to the balance between the amount of greenhouse gas emitted and the amount removed from the atmosphere. In the context of the built environment, this means designing, constructing, and operating buildings that contribute minimal carbon emissions throughout their lifecycle.

Beyond Our Immediate Environmental Impact

Our responsibility extends beyond our direct organizational activities. The built environment plays a more substantial role in the global carbon impact than many realize, contributing 40% to the world’s greenhouse gas emissions. Through our actions, we aim to not only mitigate our direct carbon footprint but also to influence and encourage our entire ecosystem – from suppliers to customers – towards more sustainable practices.

Key Areas of Focus

Our Sustainability Action Plan places particular emphasis on several strategic areas:

Cradle to Gate: We commit to understanding and optimizing the environmental impact of our materials and processes from planting to arrival at our production facility. This lifecycle perspective ensures we choose the most sustainable materials and methods available.

Regionalized Supply Chain: By prioritizing suppliers close to our manufacturing plants, we can reduce transportation emissions, support local economies, and minimize our overall environmental footprint. This regional focus strengthens communities and promotes sustainability in the broader construction industry.

Energy Efficiency: In our design and operations, energy efficiency is paramount. We are dedicated to innovating and implementing the most effective energy-saving technologies, reducing both our and our customers’ carbon impact.

Waste Reduction: Waste is a significant issue in manufacturing and construction. Our manufacturing minimizes (and in most cases eliminates) waste at every stage of our operations by recovering unused end-of-line material and recirculating to the beginning which creates a closed-loop system.

To Our Installers, Homeowners, Builders, Architects and Stakeholders

This plan is more than a pathway to achieving sustainability goals; it’s a commitment to future generations. We are key to this transition. It’s through your expertise, creativity, and dedication that these ambitions become realities. This document outlines our collective responsibilities and opportunities for impactful change.

The path to sustainability is complex and requires us to be continually learning, adapting, and innovating. However, the benefits – a healthier planet, resilient communities, and a sustainable economy – are worth every effort. Our Sustainability Action Plan is the beginning of this essential shift, and together, we will forge a more sustainable future.

Our Focus

-Industrial Hemp Fiber as Core Feedstock

-Planting / Harvesting / Processing practices

-Regionalized Supply Chain

-Manufacturing Circularity

-Powered by 100% Renewable Energy

-Operational Materials Selection

-Shipping / Transportation / Warehousing practices

-Collateral Reduction

Industrial Hemp Fiber as Core Feedstock

Industrial Hemp is a superior choice for sustainable insulation due to its eco-friendly characteristics and exceptional insulation properties. It is a rapidly renewable resource that grows quickly, requiring minimal water, no pesticides, or fertilizer, thereby reducing environmental impact. Hemp’s natural fibers offer excellent thermal insulation, keeping homes warm in winter and cool in summer, leading to energy savings. Additionally, hemp insulation is carbon negative, meaning it captures more CO2 (6500lbs/acre) than it emits during its lifecycle. This makes it not only beneficial for the environment by contributing to carbon reduction in the atmosphere but also provides a healthier living space by avoiding the use of toxic chemicals found in traditional insulation materials.

Hemp insulation is not only environmentally friendly but also offers other significant advantages. It has excellent acoustic properties, reducing noise pollution and creating a more peaceful living environment. This makes it an ideal choice for buildings located in busy urban areas or near highways. Furthermore, hemp insulation is highly durable and pest resistant, eliminating the need for frequent replacements and chemical treatments.

One of the most significant benefits of using hemp insulation is its vapor permeability, preventing the buildup of mold and mildew in the walls, which can cause health hazards. Hemp insulation also regulates humidity levels, creating a comfortable and healthy living environment.

In addition to being an excellent choice for residential buildings, hemp insulation is also suitable for commercial and industrial buildings. Its unique properties make it a great option for soundproofing, temperature control, and moisture regulation in large spaces such as offices, warehouses, and factories.

Overall, hemp insulation offers numerous advantages over traditional insulation materials. It is sustainable, eco-friendly, durable, pest-resistant, permeable, and versatile. With the increasing focus on sustainable building practices and reducing carbon footprint, hemp insulation is superior as a viable and beneficial alternative. By choosing hemp insulation for your building, you not only contribute to a greener world but also create a healthier and more comfortable living or working space.

Planting and Harvesting Hemp

Planting and harvesting hemp offer numerous benefits, including minimal water requirements and avoidance of harmful pesticides or fertilizers. By harnessing the power of hemp cultivation, we can promote sustainable agriculture, conserve natural resources, mitigate GHGs, and foster economic development in communities around the world.

Hemp has inherent deep root systems that can access groundwater more efficiently than shallow-rooted plants. This enables hemp to thrive with minimal irrigation, reducing the strain on water resources and irrigation infrastructure. By requiring less water for growth, hemp cultivation helps conserve freshwater resources, mitigating the impacts of water scarcity and drought on agriculture and ecosystems.

Lastly, hemp is naturally resistant to pests, eliminating the need for synthetic pesticides. This minimizes chemical inputs and the associated environmental risks, such as soil and water contamination, safeguarding ecosystem health and human well-being. While Hempitecture’s core product feedstock is hemp, we are continually exploring other sustainable fibers and upcycling opportunities that can be integrated into our product family. Our commitment to sustainability drives us to innovate and diversify our material sources, ensuring that we not only reduce our environmental footprint but also enhance the versatility and performance of our products. By investigating alternative fibers and upcycling waste materials, we aim to create high-quality insulation solutions that meet the evolving needs of our customers while supporting a circular economy. As we consider a wholistic view of our Sustainability Action Plan, this approach not only reinforces our dedication to ecological stewardship but also positions us as leaders in a cleaner building materials industry.

Regionalized Supply Chain

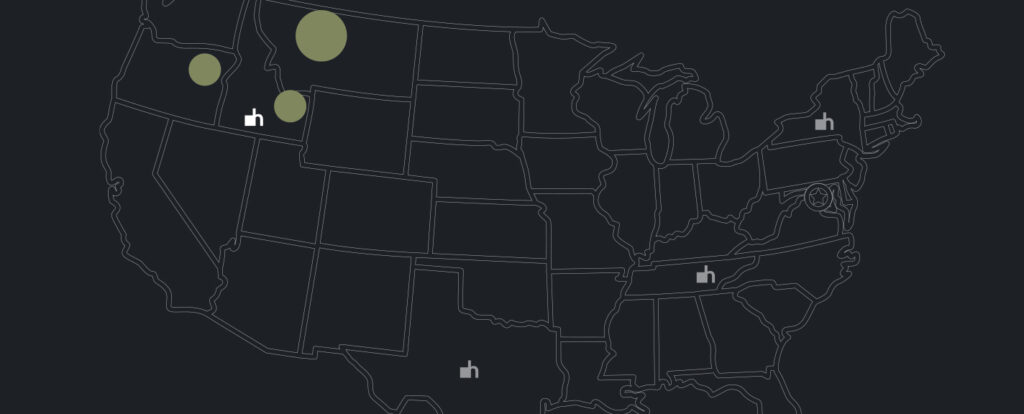

Sourcing products from a regional supply chain, plays a critical role in minimizing the carbon footprint associated with transportation. By reducing the distance goods travel from producer to consumer, the emission of greenhouse gas is significantly lower, contributing to the fight against climate change. Additionally, supporting local supply chains boosts the regional economy, encouraging money to circulate within local communities and creating jobs. It also revitalizes rural agriculture, providing farmers and producers the opportunity to thrive in a market increasingly dominated by large-scale, commercial agriculture. This regional-first approach not only fosters environmental sustainability but also strengthens community ties and promotes economic resilience. We are committed to capping the distance our feedstock travels to our manufacturing facility to no more than 500 miles.

As Hempitecture expands its manufacturing footprint across the US, we will continue to operate under this modality, while making efforts to further reduce that 500 mile benchmark. We are actively pursuing new facilities coming online in New York, Texas and Tennessee, demonstrating our commitment to expanding our production capabilities and regional presence. Concurrently, we are dedicated to bolstering a farming community that supports a regionalized supply chain, ensuring a steady and sustainable flow of raw materials. By fostering strong relationships with local farmers, we aim to create a symbiotic network that benefits both agricultural producers and our manufacturing processes.

This strategic approach not only enhances our operational efficiency but also promotes local economic growth and resilience. Through these efforts, Hempitecture is building a robust infrastructure that underpins our mission of commercializing innovative, sustainable building materials.

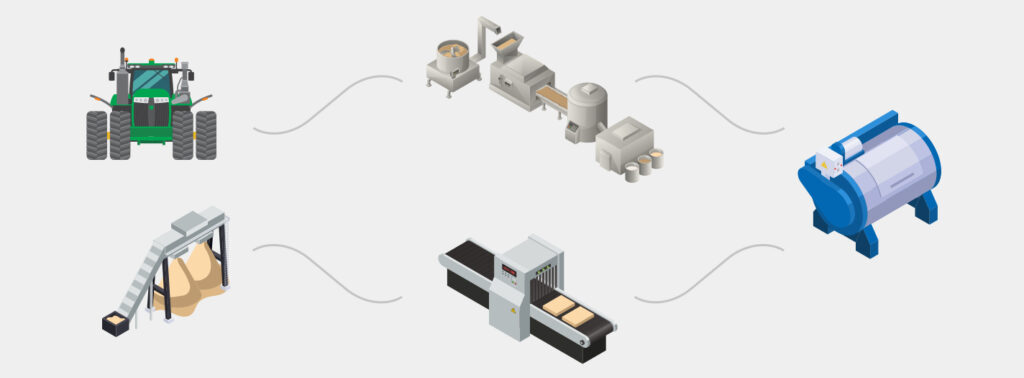

Manufacturing Circularity

Perhaps the biggest opportunity in realizing our Sustainability Action Plan, is manufacturing circularity. It is crucial in transitioning towards a sustainable future, as it redefines the traditional linear production model into a regenerative system that minimizes waste and maximizes resource efficiency. By designing products and processes that enable materials to be reused, remanufactured, and recycled, circular manufacturing reduces the environmental impact of production and consumption. This approach not only conserves natural resources but also lowers greenhouse gas emissions and reduces landfill waste. Furthermore, circular manufacturing encourages innovation in product design and materials science, fostering the development of durable, high-quality goods with extended lifecycles. It also strengthens economic resilience by creating new business opportunities and reducing dependency on finite resources.

Due to it’s natural biodegradable qualities, the manufacturing of hemp insulation will have minimal to no impact on landfilling. We repurpose all byproducts into value added materials and products. Waste fiber is repurposed back into insulation or other products, and fine dust streams are converted into a feedstock for energy generation. Embracing manufacturing circularity is essential for building a sustainable, resilient economy that prioritizes environmental stewardship and long-term prosperity.

Powered by 100% Renewable Energy

Access to clean energy has to be at the core of any Sustainability Action Plan. Producing conventional insulation products such as fiberglass and mineral wool heavily rely on fossil fuels, such as coal, natural gas, and oil, for energy in manufacturing processes. This reliance contributes significantly to carbon dioxide emissions, one of the primary greenhouse gasses responsible for climate change and ultimately amplifying the embodied carbon footprint of industrial activities

Hempitecture proudly operates a facility that is 100% powered by renewable clean energy (90% wind, 10% solar). Solar and wind energy produce no greenhouse gas emissions during operation, significantly reducing the carbon footprint associated with manufacturing building products. Unlike fossil fuel-based power, renewable energy does not emit harmful pollutants such as sulfur dioxide, nitrogen oxides, and particulate matter, leading to cleaner air and a healthier community. Lastly, Solar and wind energy systems require minimal water for operation, unlike traditional power plants, which can consume large amounts of water for cooling and other processes.

Operational Material Selection

Materials consideration in the final-mile delivery (defined as delivery of goods from our manufacturing facility to job site)of products to consumers is essential for minimizing environmental impact and promoting a more eco-friendly supply chain. Sustainable packaging and delivery materials reduce waste, decrease reliance on non-renewable resources, and lower greenhouse gas emissions associated with production and disposal. By opting for recyclable, biodegradable, or reusable packaging, we can significantly lessen our environmental footprint.

Repurposed shipping pallets play a crucial role in our sustainability and resource efficiency in logistics and supply chain management. Recycled pallets prevent old pallets from ending up in landfills and reducing environmental burden associated with disposal. By using recycled pallets, Hempitecture conserves natural resources by reducing the need for new raw materials, such as wood from forests or plastic derived from fossil fuels. By reducing the demand for new wooden pallets, repurposing helps decrease deforestation and promotes sustainable forestry practices.

Additionally, to protect our products to their final destination, we use a sustainable plastic wrap that leverages bio-assimilation technology that breaks down after 2 years, leaving no microplastics on toxins and reduces long-term pollution and waste accumulation. This return-to-origin becomes a food source for microorganisms without leaving harmful residues.

In the final-mile delivery phase, prioritizing sustainable materials reflects a commitment to comprehensive environmental stewardship and helps build trust and loyalty among eco-conscious consumers.

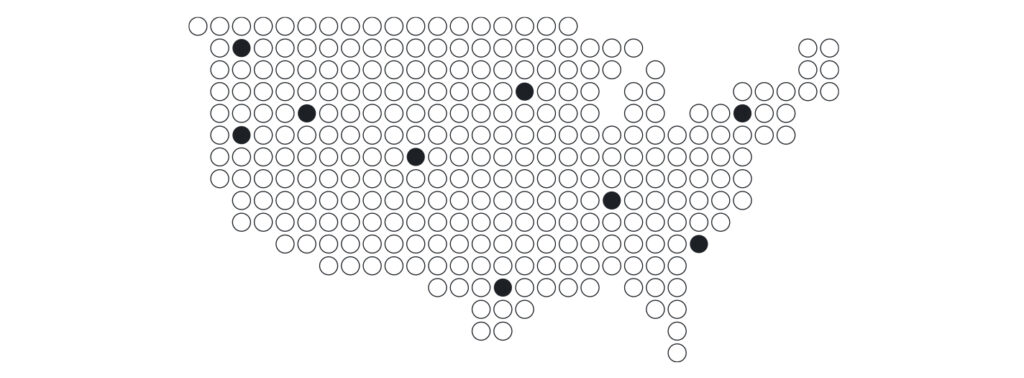

Shipping / Transportation / Warehousing

Does a larger footprint align with a Sustainability Action Plan?? Having distribution warehouses close to high population centers is crucial for several reasons. Firstly, it significantly reduces delivery times, enhancing customer satisfaction by ensuring quicker and more reliable service. Proximity to major urban areas also lowers transportation costs, as shorter travel distances mean reduced fuel consumption and lower vehicle maintenance expenses. This proximity is particularly beneficial for last-mile delivery, the most expensive and time-consuming segment of the shipping process. Additionally, strategically located warehouses can better manage inventory and respond swiftly to market demands, ensuring that popular products such as HempWool and FiberPad are always available.

From an environmental perspective, reduced transportation distances contribute to lower carbon emissions, aligning with sustainability goals. Overall, placing distribution warehouses near high population centers optimizes logistics efficiency, cuts costs, improves service quality, and supports sustainable practices. We are constantly learning from the market, and continue to throttle our distribution footprint to balance cost and accessibility to our customers.

Collateral Reduction

Limiting or eliminating printed collateral is seemingly inconsequential, but it makes a big impact. Reducing printed materials significantly lowers paper consumption, leading to a decrease in deforestation and a reduction in the use of water, energy, and chemicals involved in paper production and recycling processes. Over 95% of Hempitecture’s end-to-consumer asset library is digitized, eliminating the need for superlative paper consumption. In the minimal instances where printed assets are used, they are produced with post-consumer recycled material and non-toxic (food grade) inks. Additionally, we utilize video platforms to deliver installation guides and best practices allowing us to deliver the most current and accurate content to our community. Video allows for updates and modifications without generating additional waste, as digital files can be edited and redistributed without physical reprinting.

Forward Looking

Currently, our production facility in Jerome, ID operates on 100% renewable energy, between Wind and Solar. Our goal for future site facilities would be to replicate this operational standard through grid sourcing and on-site energy generation. Industrial Hemp Fiber is the carbon-capturing engine behind Hempitecture’s developing product portfolio, storing 6,500 lbs of biogenic carbon per acre in the Rocky Mountain Northwest, primarily in Scobey soil types. In the southeastern region, there are Loring, Memphis, and Decatur soil types, which historically have been highly productive for cotton. These soil types, paired with industrial hemp cultivation, would boost the biogenic carbon storage potential of industrial hemp fiber to an estimated 8,000 to 10,000 pounds of biogenic carbon per acre. We anticipate this to result in a biogenic sequestration of roughly 5mm lbs of CO2/yr in the southeastern region, and comparable GHG reduction of 12.5mm lbs of CO2/yr versus traditional products.

Percentage wise, these represent 60-80% carbon footprint reductions versus mineral fiber insulation products. Lifecycle analysis of hemp products typically shows lower GHG emissions compared to conventional materials. For example, the production of hemp fiber and seeds tends to have a lower carbon footprint than cotton or synthetic fibers. Hempitecture’s working LCA is indicating a negligible carbon impact, as the GaBi software being used does not account for biogenic carbon , but our eventual Environmental Product Declaration (EPD) will prove a significant decarbonized result, using a program and methodology that reflects the biogenic storage potential of industrial fiber hemp.

Industrial hemp has a favorable impact on greenhouse gas emissions, primarily due to its high carbon sequestration capability, low input requirements, and potential to replace more carbon-intensive materials. Hemp cultivation presents a promising opportunity for reducing GHG emissions and enhancing environmental sustainability in highly favorable sites throughout the United States.

In Conclusion

Hempitecture’s practices underscore our unwavering commitment to pioneering healthier building materials for people and planet. As we grow, our dedication to this Sustainability Action Plan will remain steadfast. Sustainability is not a destination but an ongoing process of evolution and innovation. Therefore, we pledge to continually refine and expand our initiatives to align with the latest advancements in sustainability practices and technologies. By harnessing the incredible potential of hemp-based materials and fostering partnerships with like-minded stakeholders, we will strive to create a built environment that promotes well-being, resilience, and environmental stewardship. Together, we can build a future where sustainable living is not just a choice but a fundamental aspect of our collective well-being.