Pioneering biobased insulation manufactured from industrial hemp and natural fibers.

High-performance, low-carbon construction

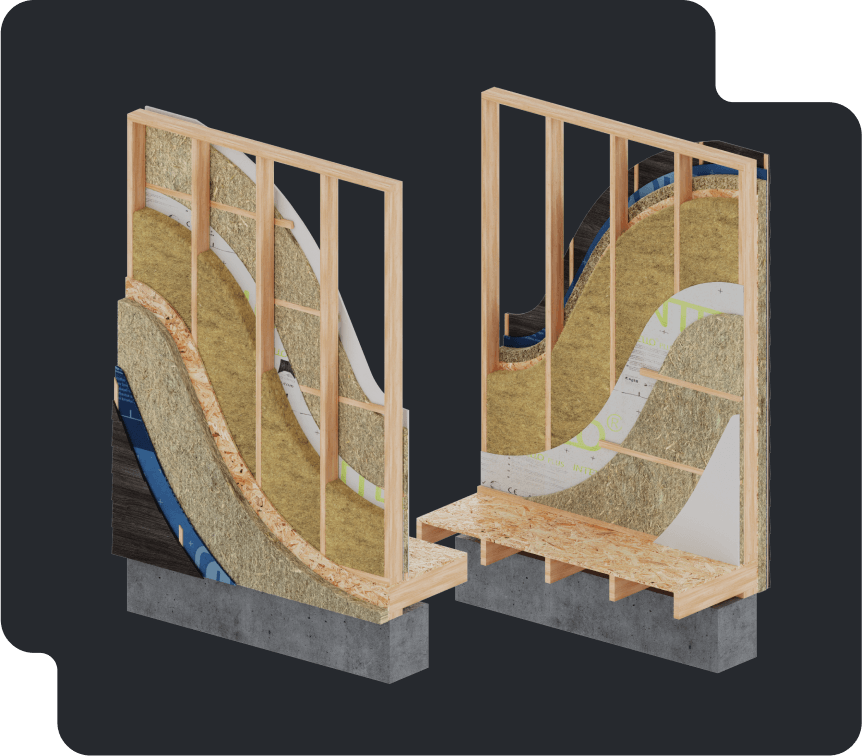

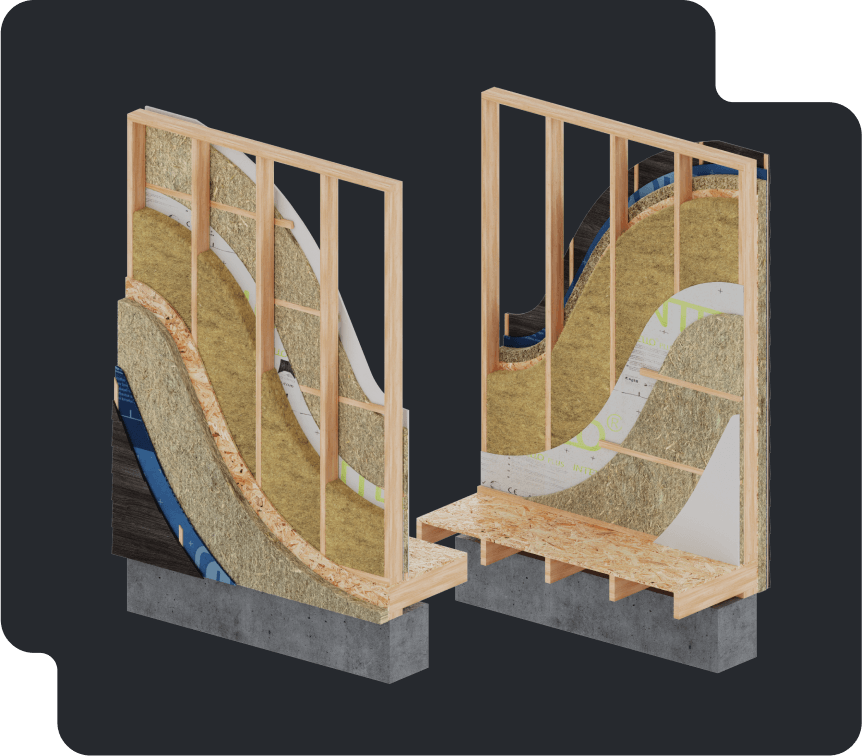

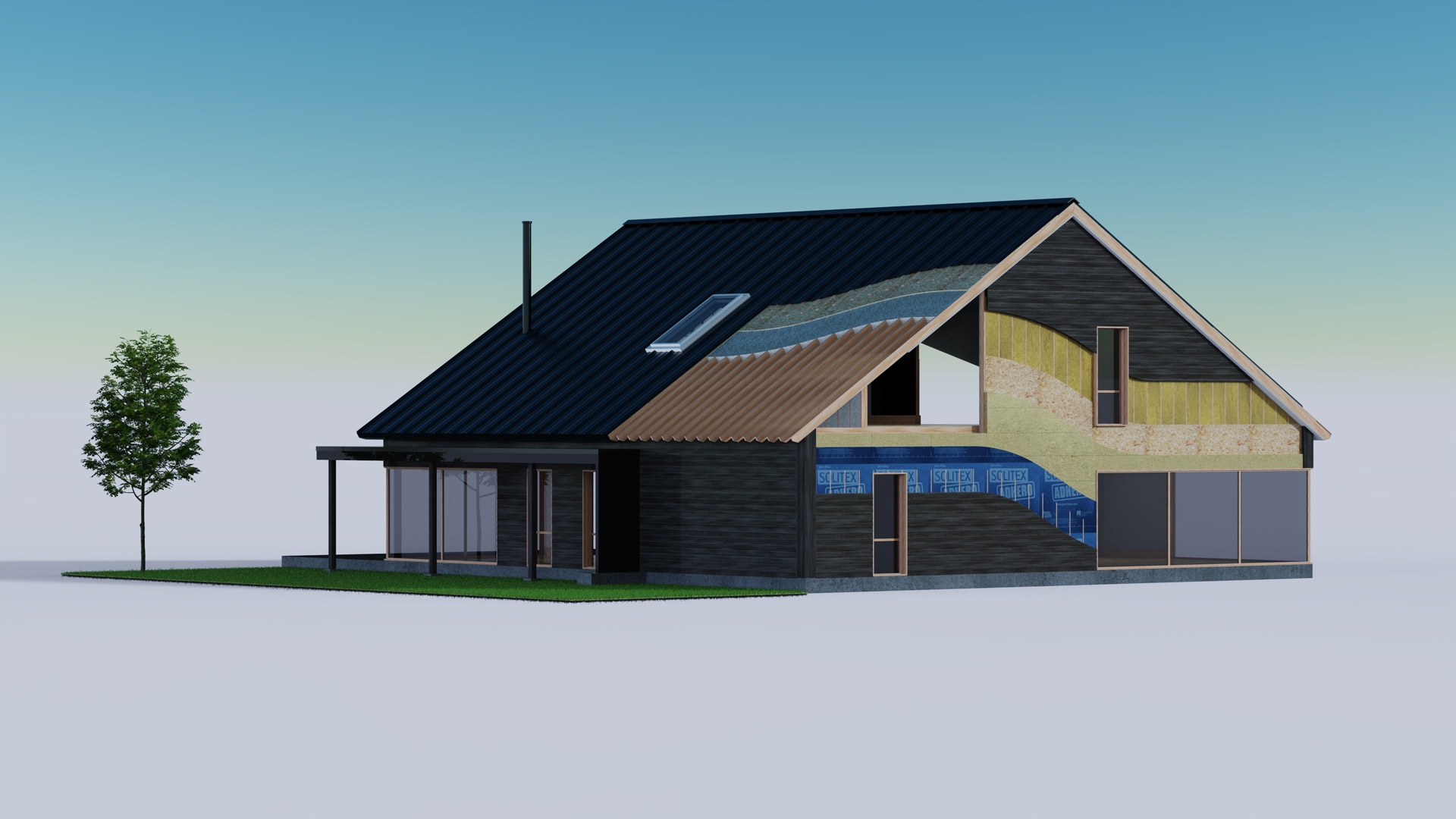

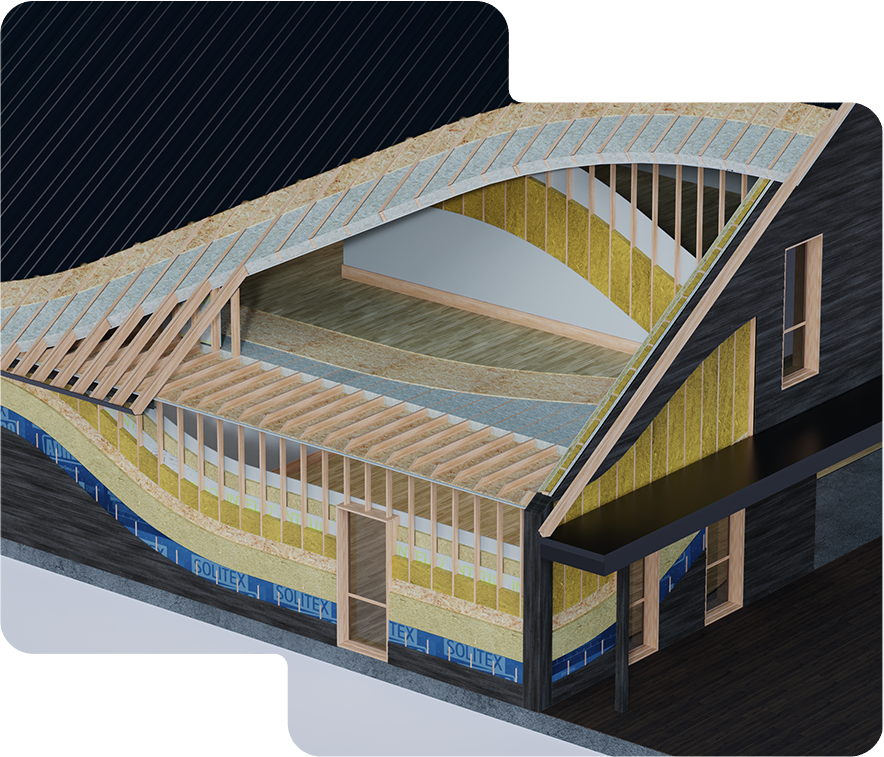

Learn more about how you can achieve an unparalleled R-value from our system of exterior, in-cavity, and interior insulating products.

See our lineup of healthy biobased insulation and acoustic products

We are here to help!

For $35, get expert assistance with project specs, material sourcing, and preliminary planning in a 30-minute consultation. For full planning services, contact us at sales@hempitecture.com. Schedule your consultation through the link on this page.

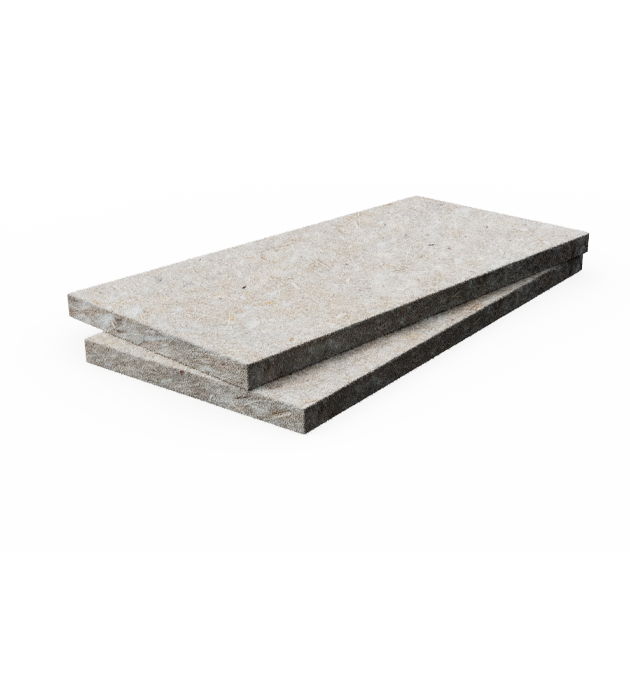

HempWool® insulation is a sustainable and natural insulation material made from a blend of hemp fibers and recycled textiles. It offers excellent thermal and acoustic properties while being safe, non-toxic, and environmentally friendly.

It is an easy to use product substitution for conventional insulation products like fiberglass or mineral wool. You can learn more here.

Ordering HempWool insulation is easy.

Check out Buy.Hempitecture.com or simply browse our Shop on our website and add the desired size and quantities (in sq.ft.) to your cart from there you can choose to have the materials delivered or you can arrange getting the materials yourselves and one of distribution hubs. Follow the checkout process, providing the necessary shipping and billing information, and complete your purchase. For any assistance or special requests, feel free to contact our sales team at sales@hempitecture.com or give us a ring at (208) 218-8698.

HempWool® is made up of approximately 92% hemp fiber and 8% textile fiber binder.

The R Value of HempWool® is 3.69 per inch.

HempWool® be used in flooring, ceilings, walls, or anywhere else traditional insulation is used. HempWool® can also be used in vans, trucks, or bus building projects.

HempWool is very easy to install and worker-friendly through a pressure-fit system. We recommend you cut it .5” thicker than the cavity you are filling it with.

Learn the techniques and tools of the trade by visiting our HempWool specific web pages.

There are a number of tools you can use to cut HempWool. A non-serated blade is best. This could be a manual insulation knife used for cutting RockWool. Additional tools include a metal cut off wheel on a handheld grinder, a FESTOOL insulation saw, or even an electric bread knife.

HempWool® can be installed by any local insulation subcontractor, general laborer, or even yourself!

It’s easy and safe to use!

You can find our HempWool® calculator by visiting our Buy Direct Platform:

Buy.Hempitecture.com

In addition to finding the total square feet of the wall(s) is by multiplying ceiling height by total wall length.

HempWool is a 1-to-1 replacement for conventional insulation products. Therefore, it works in conventional situations with 16″ OC or 24″ OC framing layouts.

HempWool works well under drywall, but can be used in conjunction with nearly every standard building material.

HempWool® has Class-E fire resistance, so although it is seen as higher on the FSI and SDI, you can protect HempWool between fire-resistant walling (both your exterior siding and interior wallboards). Due to the lack of fire resistance, it is generally approved by a case-by-case project and is not applicable for some projects.

HempWool is Vapor Permeable and Hygroscopic – meaning it can interact with moisture without any problems. HempWool helps prevent airborne moisture movement, improving building durability and longevity. HempWool disperses moisture and helps to protect the surrounding building components. It has the ability to store and release moisture without loss of its insulating properties. In fact, we’re currently doing a study on its mold resistance, since it is a great characteristic of the product. It’s not complete yet though.

ASTM Standards testing shows no mold growth. If HempWool is exposed to excessive moisture such as a flood or a persistant leak, like any product, mold can grow.

Hemp Fiber naturally repels rodents, mites, and termites because of the silica (a mineral) in the hemp plant. Hemp also has very little protein for pests and the mechanical strength of this material is too strong for anything to nest in it.

HempWool performs comparably to conventional insulation products in regards to sound attenuation. In the future, we intend to launch acoustic insulation products.

HempWool is ideal for humid environments, since the hygrometric insulation is vapor permeable and also resistant to mold. HempWool should not be exposed to excessive moisture, as excessive moisture can cause mold. Interior to a cavity that is properly air and vapor sealed, HempWool is the ideal product for humid climates.

Hempitecture works hard to keep our costs low and our operations efficient to deliver customers a cost competitive, sustainable insulation made in the United States. The reason why our products sometimes cost more than fiberglass, mineral wool, or foam based insulations is because of the current cost of our main ingredient: Hemp fiber. The industry is still nascent with vast demand for this fiber that comprises over 50% of our product cost. Once the industry benefits from greater scale, we see potential for these fiber costs to be reduced dramatically. Secondly we are working hard to produce product in multiple regions to reduce stock transfer shipping which is another significant cost driver.

Hempitecture is consistently one of the least expensive sustainable insulation choices and customers will often choose HempWool or PlantPanel over less expensive mineral wool or fiberglass alternatives because of safety, performance, and sustainability.

Our products have been approved for use by building departments across the country. Because HempWool® and hempcrete are new to the construction industry, a technical conversation is useful for most building offices and inspectors to become familiar with these materials but they are often supportive of their use once they realize the sustainability potential. It is usually up to the local building jurisdiction to decide whether or not these building materials can be permitted.

Our products are manufactured in Jerome, Idaho using regionally grown industrial hemp fiber. Our factory is not open to the public, but if you would like to visit our facility to see product before purchasing, please contact sales@hempitecture.com

Plant based products generally are more sustainable than petrochemical, synthetic, or resource extracted products. This is because plants grow quickly, and during their growth cycle, the offset and store carbon dioxide. Industrial hemp is particularly adept at this.

HempWool is currently ASTM tested for a number of criteria. With our US manufacturing facility, we intend to have our products tested and qualified for numerous certifications.

Hemp and Marijuana both derive from the cannabis Sativa family, they do share certain similarities. However, due to each plant’s biological structure, they have several and very distinct differences.

Hemp plants are slim and very tall, reaching a height between 10 and 18 ft. Hemp leaves are also very skinny and are commonly found nearer the top of the stalk alongside the trichome-rich buds. Hemp plant color varies. Some are a lighter green, while others have a greyish hue.

Historically, industrial hemp and its fibers have been used for clothes, rope, shoes, carpets, and paper. Our products are 100% THC free.

You can read about Hempitecture’s order, shipping, and return policies here on the FAQ under the Orders & Shipping and Returns, Refunds, and Exchanges tabs or contact us with any questions.

Once your order is shipped, you will receive an email notification with a tracking number. You can use this tracking number to monitor the progress of your shipment. For real-time updates, contact the shipping company directly using the provided phone numbers or the tracking number (PRO #).

The r-value of hempcrete ranges from r2.2 per inch to r2.5 per inch, dependent on density. this relatively low thermal resistance compared to other insulating materials do not take into account the thermal mass or phase shift regulating the capacity of Hempcrete.

In some instances, you can use Hempcrete for renovations. Hempcrete must be installed in a vapor open system. therefore, design considerations must be made to determine if Hempcrete is compatible with your renovation.

Cast-in-place Hempcrete is a mixed on-site, cast-on-site building method that uses temporary form boards to create the cavity in which Hempcrete is installed.Hempcrete blocks are pre-cured and delivered to the site in various dimensions. they are installed similarly to masonry-based blocks, but they are not structural or load-bearing.

Hempcrete is not intended to be a structural or load-bearing material. it cannot replace concrete. it is not intended for ground contact or below-grade applications.

Hempcrete should not be installed against osb or plywood. it is a vapor open wall assembly. consult a structural engineer for methods to gain shear value resistance without plywood or osb.

Consult our Hempbinder product guide to get an understanding of what equipment and tools are required for Hempcrete installation.

Calculate the cubic footage of your wall volume. visit www.buy.hempitecture.com to input your cubic footage to generate an estimate of how much material you need. our estimation tool will also calculate shipping rates.

Determine the cost of materials by calculating your cubic footage and getting an estimate from www.buy.hempitecture.com labor costs will vary, and the total cost of your installation will be based on local labor rates and the complexity of your design.

Yes. you can book a consultation through www.hempitecture.com

In some instances, Hempitecture can train contractors to assist in completing a project.

Buy Hempcrete materials through www.buy.hempitecture.com.

No. Hempcrete requires vapor open wall designs and should be finished with lime plaster or vented siding/cladding.

Hempcrete is an accepted building strategy for 1-story construction projects as referenced in the ICC Appendix. however, information should be presented to local code compliance officials to ensure its acceptance on a local level.

Hempcrete should be finished with vapor open materials or assemblies. lime plaster is recommended to be applied directly to the surface of a Hempcrete wall. alternatively, vented rain screen details or back vented siding could be applied on the exterior.

Hempcrete should be finished with vapor open materials or assemblies. lime plaster is recommended to be applied directly to the surface of a Hempcrete wall. alternatively, vented rain screen details or back vented siding could be applied on the exterior.

Our product guide and our blog is a great place to start. there are also numerous published books that provide more information on Hempcrete.

Ordering from Hempitecture is easy.

Check out Buy.Hempitecture.com or simply browse our Shop on our website and add the desired materials and quantities to your cart. From there you can choose to have the materials delivered or you can arrange picking up the materials yourself at one of our distributions hubs (select pick-up at buy.hemepitecture.com to see addresses). Follow the checkout process, providing the necessary shipping and billing information, and complete your purchase. For any assistance or special requests, feel free to contact our sales team at sales@hempitecture.com or give us a ring at (208) 218-8698.

When you place an order with us at buy.hempitecture.com, we take care of arranging and purchasing the shipping as a courtesy to you. We do not charge any additional fees for booking your shipment. However, it’s important to note that any changes or modifications to your booking, requested after it has been processed, may result in additional costs. These extra charges are determined by the third-party logistics companies, and we are unable to control or influence them.

If you require our sales team to draw up a payable invoice for your order and quote and book the shipping manually, a 5% markup on the shipping costs will be assessed to encourage you to use the ordering tools we’ve built.

Hempitecture works with third-party shipping companies. Once you purchase your order, we will handle the shipping arrangements and share the tracking information (via a pro-number) with you once the shipment has been picked up.

After your order has been processed and shipped, we will send you an email notifications with your PRO# that you can use to monitor the progress of your shipment.

To stay up to date on the status of your delivery, we recommend reaching out directly to the shipping company responsible for your package. You can contact them using the phone numbers provided in the shipping confirmation email or through the tracking number (PRO #) provided. The logistics company will be able to provide you with real-time information about the whereabouts of your shipment and any updates regarding its delivery.

If the inventory is in stock, it usually takes about one week to receive your insulation from payment. If an internal stock transfer is required to supply the warehouse, delivery could take 2-3 weeks from payment.

If you prefer to book your own shipment or retrieve the materials yourself, we offer that flexibility. Simply get in touch with our team at orders@hempitecture.com, and we will assist you in making the necessary arrangements. You can provide your own shipping details, such as the preferred carrier and shipping method, or coordinate a pickup from one of our distribution hubs.

If your delivery arrives with severe damage, we advise you not to accept the package. Instead, take photos of the damage and reach out to our Logistics team at orders@hempitecture.com.

They will guide you through the necessary steps to resolve the issue.

If the damage is minor, we recommend accepting the delivery and following up with the Hempitecture team. If a shipment is refused for minor or incidental damage, the customer may be responsible for additional shipping charges.

Currently, we do not offer international shipping outside of Canada. However, we can deliver to anywhere within the United States, including shipping docks. If you are interested in shipping internationally, you will need to book your own freight from the US. For more information, please contact us at orders@hempitecture.com.

At Hempitecture, we strive to provide you with high-quality sustainable materials. If you encounter any issues with your order or need to make a return or exchange, please review the following information:

Returns and Exchanges:

Return Process:

Refunds:

Damaged or Defective Products:

Note: All refunds, returns, and exchanges are subject to our discretion and compliance with the stated policies. We reserve the right to refuse returns or exchanges that do not meet the specified requirements.

If you have any further questions or need assistance regarding returns, refunds, or exchanges, please don’t hesitate to contact our customer support team at orders@hempitecture.com. We are here to help and ensure your satisfaction with our products.

When you place an order with us, we take care of arranging and purchasing the shipping as a courtesy to you. We do not charge any additional fees for booking your shipment using buy.hempitecture.com. If we have to quote and arrange shipping off-platform, a 5% fee is assessed. It’s important to note that any changes or modifications to your booking, requested after it has been processed, may result in additional costs. These extra charges are determined by the third-party logistics companies, and we are unable to control or influence them.

Hempitecture currently works with third-party shipping companies to move your order via Full Truck Load (FTL) or Less than Truckload (LTL) carriers. Once you purchase your order, we will handle the shipping arrangements and share the tracking information (via a pro-number) with you once the shipment has been picked up.

If you did not select the lift gate option, then you will need a forklift or loading deck to receive your pallets.

An appointment is only guaranteed if you select that option when checking out.

After your order has been processed and shipped, we will send you an email notification. This email will provide you with a tracking number (PRO #) that you can use to monitor the progress of your shipment.

To stay up to date on the status of your delivery, we recommend reaching out directly to the shipping company responsible for your package. You can contact them using the phone numbers provided in the shipping confirmation email or through the tracking number (PRO #) provided. The logistics company will be able to provide you with real-time information about the whereabouts of your shipment and any updates regarding its delivery.

If the inventory is in stock, it usually takes about one week to receive your insulation. If we need to transfer inventory to the nearest warehouse to fulfill your order, it could take 2-3 weeks to receive your insulation. Please allow for extra time when fulfilling your order as you do not want to have a construction project delay due to shipping setbacks.

If you would like to place a larger order, please contact us at sales@hempitecture.com in order to best prepare your shipment.

If you prefer to book your own shipment or retrieve the materials yourself, we offer that flexibility. Simply get in touch with our team at orders@hempitecture.com, and we will assist you in making the necessary arrangements. You can provide your own shipping details, such as the preferred carrier and shipping method, or coordinate a pickup from one of our distribution hubs.

If your delivery arrives with severe damage, we advise you not to accept the package. Instead, take photos of the damage and reach out to our Logistics team at orders@hempitecture.com.

They will guide you through the necessary steps to resolve the issue.

If the damage is minor, we recommend accepting the delivery and following up with the Hempitecture team. If a shipment is refused for minor or incidental damage, the customer may be responsible for additional shipping charges.

Currently, we do not offer international shipping except for Canada. However, we can deliver to anywhere within the continental United States, including shipping docks. If you are interested in shipping internationally, you will need to book your own freight from the US. For more information, please contact us at orders@hempitecture.com.

Hempitecture was founded with the idea that healthy, sustainable materials can help build a better world. These materials can help build a better world by contributing to our health, saving energy, and storing carbon dioxide. We achieve our mission by focusing on biobased, natural building materials that are designed to replace conventional, toxic materials.

Hempitecture’s headquarters are in Idaho with a corporate office in Ketchum and our manufacturing facility in Jerome, Idaho.

We have warehouses located across the country for local distribution. Check buy.hempitecture.com to see our latest warehouse locations under the pick-up option.

Hempitecture has realized its manufacturing vision through a consortium of private and public sponsors including a $4.6mm Reg CF investment round. To participate in future Hempitecture equity fundraises, please follow along at wefunder.com/hempitecture

Hempitecture began in 2013 as part of a college senior thesis at Hobart & William Smith College by Hempitecture CEO Matthew Mead. In his evaluation of different natura building material solutions, Mattie decided hemp-based materials offered the greatest promise and trademarked and launched Hempitecture!

In 2018 after completing Idaho Basecamp and while working on the Highland Hemp House, Mattie reconnected with high school classmate Tommy Gibbons and the two founded Hempitecture as a public benefit corporation with a vision to scale sustainable building materials across the United States.

Get the latest on products and news straight to your inbox.

Get the latest on products and news straight to your inbox.